|

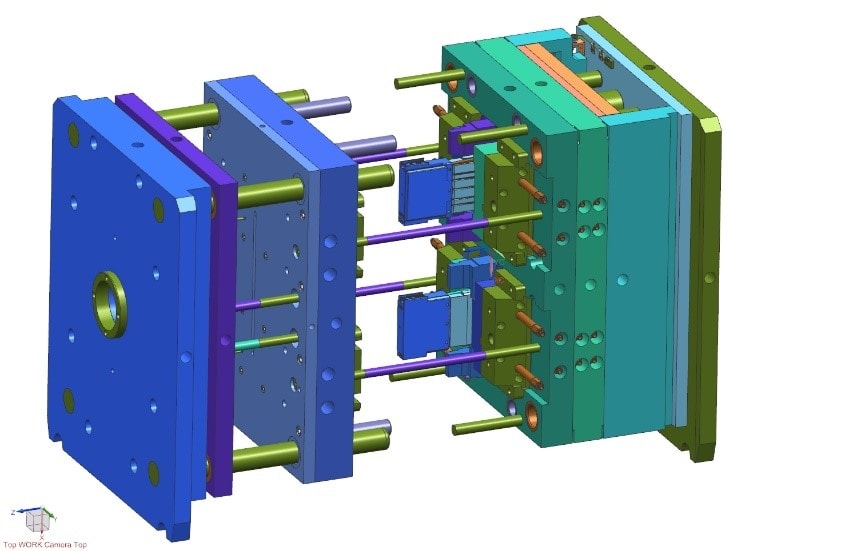

Injection mold designers must use careful consideration when designing a mold for a complex part design. Intricate plastic injection molded parts may contain several critical areas that must be carefully designed to meet part specifications. Parts that contain a very thin wall, for example, would be a critical fill area. It takes expertise in mold design to fill a part completely without any overfill or underfill while still maintaining the integrity of such a thin critical dimension.

Critical areas should be identified on the part print, and throughout the entire mold design phase. Sophisticated CAD/CAM software is used to develop a viable tool design given all part design specifications and other exterior design considerations such as the specified material and press size. With a superior design software program like Unigraphics or SolidWorks, mold designers can develop the entire mold construction phase and test critical areas with computer simulation software. This advanced quality planning phase is crucial to constructing precision molds to customer specification, and within the established lead time. The part print will also contain specific information such as the resin used and the surface finish or texture required of the final part. Any restrictions on knit or parting lines must be identified for proper gating. It takes an experienced mold designer to implement a successful tool design and construction of a precision mold for injection molded parts with a complex design. Download our FREE Book on Design Considerations for Different Molds, and contact us today to learn about our discount and rebate programs. Michiana Global Mold is an experienced injection mold design and construction company, supplying precision tools to various industries since 1964. We are an ISO registered mold shop, satisfying the strict requirements of the Automotive industry with high quality complex molds. Contact us today to speak with one of our knowledgeable engineers for a FREE design consultation.

0 Comments

Leave a Reply. |

Archives

August 2017

Categories

All

|

RSS Feed

RSS Feed